The 7th edition focuses on foundational sterile processing techniques, with a corresponding workbook available․ Resources, including a PDF, aid learning and test preparation, as of August 1, 2025․

Overview of the Textbook

The Basics of Sterile Processing, 7th Edition, serves as a comprehensive guide for individuals entering or currently working within the Central Sterile Services Department․ This textbook meticulously details the critical processes involved in decontamination, cleaning, and sterilization of medical instruments and equipment․

It emphasizes adherence to established standards from organizations like AAMI and CDC, ensuring safe patient care․ The text covers hand and power instruments, alongside the unique challenges presented by endoscope processing․

A companion workbook reinforces learning, offering practical exercises and case studies․ While a completely free PDF version is sought after by students, official access typically requires purchase or institutional subscription․ The 9th edition is the current test standard, but the 7th remains a valuable resource․

Importance of Sterile Processing

Sterile processing is paramount in healthcare, directly impacting patient safety and preventing Healthcare-Associated Infections (HAIs)․ The 7th edition of this textbook underscores this vital role, detailing how meticulous decontamination and sterilization eliminate microorganisms, including resilient spores․

Properly processed instruments are sterile – completely devoid of living organisms – a critical requirement for surgical procedures and invasive treatments․ The text highlights the consequences of compromised sterilization, emphasizing the need for rigorous quality control, utilizing both biological and chemical indicators․

Understanding the workflow, from receiving to monitoring, is crucial․ Access to resources like the workbook and, ideally, a PDF version, facilitates mastery of these essential techniques, ultimately safeguarding patients and upholding healthcare standards․

Target Audience for the 7th Edition

This 7th edition is specifically designed for individuals entering or currently working in sterile processing departments․ It caters to Sterile Processing Technicians, Central Service professionals, and those seeking certification within the field․ The textbook serves as a core resource for institutional training programs․

Students enrolled in sterile processing courses will find the content comprehensive and aligned with industry standards․ The accompanying workbook provides practical exercises to reinforce learning․ Those preparing for certification exams, potentially utilizing a PDF for convenient study, will benefit from its detailed explanations․

Even experienced professionals can utilize this edition to refresh their knowledge and stay current with evolving best practices․

Core Principles of Sterile Processing

Sterilization, disinfection, and cleaning are fundamental, alongside understanding microbial life cycles – crucial concepts detailed within the 7th edition resources․

Decontamination Processes

Decontamination is the initial critical step, encompassing cleaning to remove visible soil, followed by disinfection – eliminating most microorganisms, but not necessarily spores․ Sterilization, the highest level, destroys all microbial life․

The 7th edition emphasizes proper rinsing techniques, specifically using sterile distilled water for endoscopes and accessories, ensuring complete removal of cleaning agents․ Understanding these processes is vital for preventing healthcare-associated infections․

Effective decontamination relies on adherence to established guidelines, including those from AAMI and the CDC, detailed within the textbook and supplemental materials․ The workbook provides practical exercises to reinforce these principles․ Accessing a PDF version can aid in convenient study․

Cleaning vs․ Disinfection vs․ Sterilization

The 7th edition clearly delineates these processes: cleaning removes visible debris; disinfection eliminates most microorganisms except spores; and sterilization destroys all microbial life․ This hierarchy is fundamental to preventing infection․

Understanding the differences is crucial․ Disinfection utilizes chemical agents, while sterilization employs methods like steam, EtO gas, or hydrogen peroxide plasma․ The textbook emphasizes that a properly cleaned item is essential before disinfection or sterilization can be effective․

Resources, including a potential PDF version of “The Basics of Sterile Processing”, reinforce these concepts․ The accompanying workbook offers practical application, solidifying comprehension of these vital distinctions for sterile processing technicians․

Sterilization Methods – A Comprehensive Look

The 7th edition provides detailed coverage of key sterilization methods․ Steam sterilization, utilizing high-pressure saturated steam, remains the most widely used and reliable method․ Ethylene Oxide (EtO) sterilization is explored for heat-sensitive items, alongside its safety considerations․

Furthermore, the text examines Hydrogen Peroxide Gas Plasma sterilization, a lower-temperature alternative․ Each method’s principles, advantages, disadvantages, and appropriate applications are thoroughly explained․

Access to supplemental materials, potentially including a PDF of “The Basics of Sterile Processing”, and the associated workbook, enhances understanding․ These resources aid in mastering cycle monitoring and quality control for each sterilization process․

Steam Sterilization

Steam sterilization, a cornerstone of sterile processing, utilizes moist heat under pressure to destroy all microorganisms, including bacterial spores․ The 7th edition details crucial parameters like temperature, pressure, and exposure time for effective sterilization cycles․

Proper loading techniques, ensuring steam penetration, are emphasized․ Understanding different types of steam sterilizers – gravity displacement and pre-vacuum – is vital․

Resources like the accompanying workbook and potential PDF versions of “The Basics of Sterile Processing” reinforce cycle monitoring and biological indicator (BI) interpretation․ Mastering steam sterilization is fundamental, as it’s the most widely used method, and the textbook provides a comprehensive guide․

Ethylene Oxide (EtO) Sterilization

Ethylene Oxide (EtO) sterilization, detailed in the 7th edition, is a low-temperature gas sterilization method ideal for heat-sensitive devices․ The textbook explains the complex chemical process, emphasizing safety protocols due to EtO’s toxicity and flammability․

Critical factors include gas concentration, humidity, temperature, and exposure duration․ Proper aeration is paramount to remove residual EtO from processed items․ The workbook likely provides practice calculations for cycle parameters․

While a free PDF of the complete textbook may be elusive, understanding EtO sterilization’s nuances – including monitoring with chemical indicators (CIs) – is crucial for comprehensive sterile processing knowledge․

Hydrogen Peroxide Gas Plasma Sterilization

Hydrogen Peroxide Gas Plasma sterilization, covered in the 7th edition, utilizes vaporized hydrogen peroxide to achieve sterilization at lower temperatures․ This method is suitable for a wide range of medical devices, particularly those damaged by heat or moisture․

The textbook details the process: hydrogen peroxide is vaporized, then excited into a plasma state using radiofrequency energy, effectively destroying microorganisms․ Cycle parameters, including exposure time and concentration, are vital for efficacy․

Finding a free PDF of the entire textbook may prove difficult, but mastering this technique – and understanding its monitoring requirements – is essential․ The associated workbook likely offers practical exercises․

Instrumentation and Equipment

The 7th edition details processing of hand and power instruments, plus complex endoscopes․ Accessing a free PDF may aid understanding of these crucial tools․

Hand Instruments

Hand instruments, foundational to surgical procedures, require meticulous processing․ The 7th edition likely details proper cleaning, inspection, and packaging techniques for various types – forceps, scalpel handles, retractors, and more․

Understanding instrument materials (stainless steel, titanium) is crucial, influencing cleaning agent selection and sterilization methods․ The text probably emphasizes disassembly for thorough cleaning, removing bioburden to prevent corrosion and ensure effective sterilization․

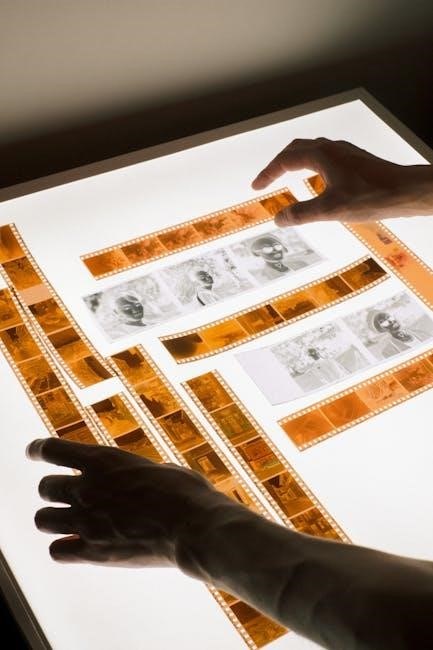

A PDF version of “The Basics of Sterile Processing” could offer visual aids demonstrating proper handling and identifying potential damage․ Maintaining instrument integrity extends their lifespan and patient safety․ Proper workflow is key․

Power Instruments

Power instruments – drills, saws, and laparoscopic devices – present unique reprocessing challenges․ The 7th edition likely details specialized cleaning protocols due to their complex designs and internal channels․ Disassembly is often required, demanding careful attention to manufacturer instructions․

Lubrication is critical; improper cleaning can remove lubricants, leading to malfunction․ The textbook probably stresses the importance of verifying functionality post-sterilization․ A PDF resource could illustrate disassembly/assembly steps․

Inspection for worn or damaged components is paramount․ Power cords and insulation require particular scrutiny․ Effective sterilization relies on complete cleaning and proper packaging to ensure sterilant contact․

Endoscopes – Processing Challenges

Endoscopes, with their intricate channels, pose significant reprocessing hurdles․ The 7th edition likely emphasizes meticulous cleaning to prevent biofilm formation, a common issue․ Thorough rinsing with sterile distilled water, as noted in resources, is crucial after disinfection․

High-level disinfection (HLD) is standard, but sterilization is preferred when possible․ Documentation of leak tests and channel patency is vital․ A PDF version of the textbook might include detailed diagrams of endoscope anatomy and cleaning protocols․

Proper drying is essential to prevent internal corrosion․ Reprocessing requires specialized equipment and trained personnel to ensure patient safety and device longevity․

The Sterile Processing Workflow

The workflow encompasses receiving, cleaning, inspection, assembly, packaging, and sterilization, with monitoring at each stage․ PDF resources support understanding these critical steps․

Receiving and Preparation

Receiving and preparation are the initial phases of the sterile processing workflow․ Instruments arrive from various departments, requiring careful inspection for damage, cleanliness, and proper functionality․

This stage involves sorting, pre-cleaning to remove gross debris, and documenting the condition of each item․ Proper handling is crucial to prevent contamination and ensure staff safety․

The 7th edition materials, and supplemental resources like a potential PDF version of “The Basics of Sterile Processing”, emphasize meticulous attention to detail during this preparatory step․

Effective preparation directly impacts the success of subsequent cleaning and sterilization processes, ultimately safeguarding patient safety․ Careful documentation is also essential․

Cleaning and Inspection

Cleaning and inspection represent a critical juncture in sterile processing․ Following receiving, instruments undergo thorough cleaning to remove all visible soil, blood, and tissue․ This process utilizes enzymatic detergents and specialized brushes, adhering to manufacturer’s instructions․

Detailed inspection follows cleaning, identifying any damage – cracks, breaks, or malfunctioning parts – that could compromise sterilization․

Resources like the 7th edition textbook and potentially available PDF versions stress the importance of following established protocols․

Proper cleaning and inspection are paramount; they directly influence the efficacy of sterilization and prevent potential healthcare-associated infections․ Documentation of findings is also vital for quality control․

Assembly and Packaging

Assembly and packaging are crucial steps ensuring instrument sets maintain sterility post-processing․ Instruments are carefully assembled according to established procedure sets, grouping items for specific surgical procedures․

Appropriate packaging materials – wraps, containers, or pouches – are selected based on the sterilization method and instrument characteristics․ These materials must allow sterilant penetration and maintain a sterile barrier․

The 7th edition textbook, and supplemental materials like a potential PDF, emphasize proper wrapping techniques and indicator placement․

Correct packaging protects instruments during transport and storage, preserving sterility until use․ Accurate documentation of the assembly and packaging process is essential for traceability․

Sterilization Cycle Monitoring

Sterilization cycle monitoring verifies that the sterilization process effectively achieves sterility․ This involves utilizing both chemical indicators (CIs) and biological indicators (BIs)․ CIs demonstrate that physical conditions were met, while BIs confirm microbial inactivation․

The 7th edition textbook details proper BI handling, incubation, and interpretation of results․ Monitoring ensures each cycle consistently delivers a sterile outcome․

Documentation of monitoring results is paramount, providing a record of sterilization effectiveness․

Access to resources, potentially including a PDF version of the textbook, aids in understanding these critical procedures․ Consistent monitoring safeguards patient safety and maintains the integrity of sterile supplies․

Quality Control and Assurance

Quality control relies on biological and chemical indicators, alongside meticulous documentation, as detailed in the 7th edition and related resources․

Biological Indicators (BIs)

Biological Indicators (BIs) are crucial for verifying sterilization effectiveness, directly assessing microbial inactivation․ They contain highly resistant bacterial spores – typically Geobacillus stearothermophilus – ensuring a robust challenge to the sterilization process․

Successful BI results demonstrate that the sterilizer achieved conditions lethal to all microorganisms․ Regular BI testing, as outlined in the 7th edition, is paramount for quality assurance․

Proper handling, incubation, and interpretation of BI results are essential․ The textbook details protocols for BI usage, including frequency, placement within the load, and appropriate record-keeping․ Accessing supplemental materials, potentially including a PDF version of the textbook, can reinforce understanding of these critical procedures;

Chemical Indicators (CIs)

Chemical Indicators (CIs) serve as a visual confirmation that specific sterilization parameters have been met, though they don’t guarantee sterility․ These indicators change color when exposed to heat, steam, or chemical sterilants, providing a quick read of process conditions․

Various types of CIs exist – Class 1, 2, 3, 4, 5, and 6 – each responding to different sterilization variables․ The 7th edition details the appropriate CI selection based on the sterilization method employed․

While CIs are convenient, they are not a substitute for Biological Indicators (BIs)․ Resources, potentially including a PDF of the textbook, emphasize the importance of using both for comprehensive monitoring and documentation, ensuring patient safety and regulatory compliance․

Documentation and Record Keeping

Meticulous documentation and record keeping are paramount in sterile processing, ensuring traceability and accountability․ The 7th edition stresses the importance of maintaining detailed logs of sterilization cycles, including date, time, load identification, sterilizer ID, and indicator results – both Chemical Indicators (CIs) and Biological Indicators (BIs)․

Accurate records demonstrate adherence to established protocols and facilitate investigations in the event of a sterilization failure․ Proper documentation supports quality control and is crucial for meeting Joint Commission requirements and AAMI standards․

Access to a PDF version of the textbook can aid in understanding specific record-keeping guidelines, ensuring compliance and patient safety within the sterile processing workflow․

Safety in Sterile Processing

The 7th edition emphasizes Personal Protective Equipment (PPE), handling hazardous materials, and ergonomics․ A PDF resource supports safe practices within the department․

Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is crucial in sterile processing to safeguard personnel from potential hazards․ The 7th edition textbook likely details appropriate PPE selection and usage, covering items like gloves, gowns, masks, and eye protection․

Proper glove selection is vital, considering material compatibility with cleaning agents and sterilization processes․ Gowns provide a barrier against contamination, while masks and eye protection shield against aerosols and splashes․

Resources, potentially including a PDF version of the textbook, emphasize correct donning and doffing procedures to prevent self-contamination․ Understanding PPE limitations and ensuring proper fit are also key components of a robust safety program․ Adherence to these guidelines minimizes risks within the sterile processing environment․

Handling Hazardous Materials

Sterile processing frequently involves exposure to potentially hazardous materials, demanding strict adherence to safety protocols․ The 7th edition textbook likely dedicates a section to safe handling practices, covering chemical disinfectants, sterilants like Ethylene Oxide (EtO), and contaminated instruments․

Proper ventilation, spill control procedures, and the use of appropriate Personal Protective Equipment (PPE) are paramount․ Understanding Safety Data Sheets (SDS) for each chemical is essential for recognizing hazards and implementing correct responses․

Resources, potentially including a PDF study guide, will emphasize proper waste disposal methods for hazardous materials․ Training on recognizing and mitigating risks associated with these substances is crucial for maintaining a safe work environment within the sterile processing department․

Ergonomics and Injury Prevention

Sterile processing roles often involve repetitive motions, prolonged standing, and heavy lifting, increasing the risk of musculoskeletal injuries․ The 7th edition textbook likely emphasizes ergonomic principles to minimize these risks, promoting safe work practices․

Proper lifting techniques, workstation setup, and regular stretching exercises are crucial components of an effective injury prevention program․ Adjusting equipment height and utilizing assistive devices can reduce strain on the body․

Access to resources, potentially a PDF supplement, will detail strategies for recognizing early signs of discomfort and implementing corrective measures․ Prioritizing employee well-being through ergonomic training is vital for a sustainable and productive sterile processing department․

Regulations and Standards

Sterile processing adheres to AAMI standards, CDC guidelines, and Joint Commission requirements, ensuring patient safety and regulatory compliance within healthcare facilities․

AAMI Standards

AAMI (Association for the Advancement of Medical Instrumentation) standards are pivotal in sterile processing, dictating best practices for reprocessing medical devices․ These standards cover a broad spectrum, from instrument cleaning and disinfection to sterilization and packaging․

Compliance with AAMI guidelines—like those for steam, EtO, and hydrogen peroxide sterilization—is crucial for ensuring device safety and effectiveness․ The 7th edition textbook likely emphasizes adherence to current AAMI recommendations․

Regular updates to AAMI standards reflect advancements in technology and infection control․ Healthcare facilities rely on these standards to establish robust sterile processing protocols, minimizing risks to patients and staff․ Resources and training materials often reference AAMI documentation․

CDC Guidelines

The Centers for Disease Control and Prevention (CDC) provides essential guidelines for infection control practices within healthcare settings, directly impacting sterile processing departments․ These guidelines cover crucial areas like environmental cleaning, hand hygiene, and the prevention of healthcare-associated infections (HAIs)․

CDC recommendations inform the development of facility policies and procedures, ensuring a safe environment for both patients and sterile processing personnel․ The 7th edition textbook likely integrates CDC guidance on topics such as appropriate disinfectant use and outbreak management․

Staying current with CDC updates is vital, as guidelines evolve based on emerging research and infection trends․ Adherence to CDC recommendations is a cornerstone of effective infection prevention in healthcare․

Joint Commission Requirements

The Joint Commission, an independent, non-profit organization, accredits and certifies healthcare organizations nationwide․ Accreditation signifies a commitment to quality patient care and adherence to rigorous standards, significantly impacting sterile processing departments․

Joint Commission requirements encompass all aspects of sterile processing, including documentation, equipment maintenance, personnel competency, and quality control․ The 7th edition textbook likely addresses these standards, preparing technicians for surveys and audits․

Compliance with Joint Commission standards is crucial for maintaining accreditation and ensuring patient safety․ Regular self-assessments and performance improvement initiatives are essential for meeting these demanding requirements․

Workbook and Supplemental Materials

A dedicated workbook by Nancy Chobin complements the 7th edition, offering practical exercises․ Supplemental online resources and practice questions enhance learning․

Utilizing the Workbook for the 7th Edition

The workbook serves as a crucial companion to “The Basics of Sterile Processing, 7th Edition,” reinforcing core concepts through practical application․ It’s designed to build competency in essential skills, offering a hands-on learning experience beyond the textbook․

Exercises within the workbook directly correlate with the textbook’s chapters, allowing students to test their understanding and identify areas needing further review․ Case studies and practice questions simulate real-world scenarios encountered in a sterile processing department․

While a freely available PDF of the textbook itself is sought after, the workbook is often purchased separately to maximize learning․ It’s a valuable tool for both aspiring and current sterile processing professionals seeking to enhance their knowledge and skills․

Online Resources and Support

Sterile Processing University offers resources to supplement “The Basics of Sterile Processing, 7th Edition․” While a free PDF of the textbook remains elusive, online platforms provide valuable support for students․ Amazon hosts the textbook and workbook, facilitating purchase and access to reviews․

Discussion forums and online communities allow learners to connect, share insights, and ask questions related to the material․ These platforms often feature supplemental materials and practice quizzes․

Searching for the “9th edition” may yield relevant information, as it’s the current focus for some educational programs․ However, ensure alignment with the 7th edition’s content for accurate study․

Practice Questions and Case Studies

Effective learning requires applying knowledge, and the 7th edition materials support this through practice․ While a freely available PDF of the complete textbook is difficult to find, utilizing the accompanying workbook is crucial․ It contains targeted questions designed to reinforce key concepts in sterile processing․

Focus on understanding the principles of decontamination, sterilization methods, and instrument handling․ Seek out additional online quizzes and case studies to broaden your assessment skills․

Reviewing real-world scenarios helps bridge the gap between theory and practice, preparing you for certification exams and professional challenges․ Remember to prioritize resources aligned with the 7th edition’s content․